Cyclone dust collector

Usage Introduction

Cyclone dust collectoris a horn curved body cone inclined bottom type dust collector. The dust concentration at the inlet should be less than 50g/m3, the inlet speed should not be less than 18 m/s, and the dust particles should not be more than 1mm. It is suitable for general industrial ventilation and dust removal systems, and the recovery of heavy materials in industrial tail gas, such as metallurgy, electric power, mechanical processing, petrochemical, building materials and other departments, plus appropriate internal weighing, can be used for wear or corrosive occasions, but can not use sticky dust.

Specific Features

cyclone dust collector is a dust removal device that uses the centrifugal force generated by the rotating airflow to separate the dust particles from the combined dust airflow. It has a simple structure, small size, no special ancillary equipment, low cost. Medium resistance, no moving parts in the device, easy operation and maintenance.

Cyclones are generally used to capture particles above 5-15 microns. The dust removal efficiency can reach more than 80%, and the dust removal efficiency of the special cyclone dust collector can reach more than 5% after improvement in recent years. A disadvantage of cyclones is that they are not very efficient at capturing particles smaller than 5 microns.

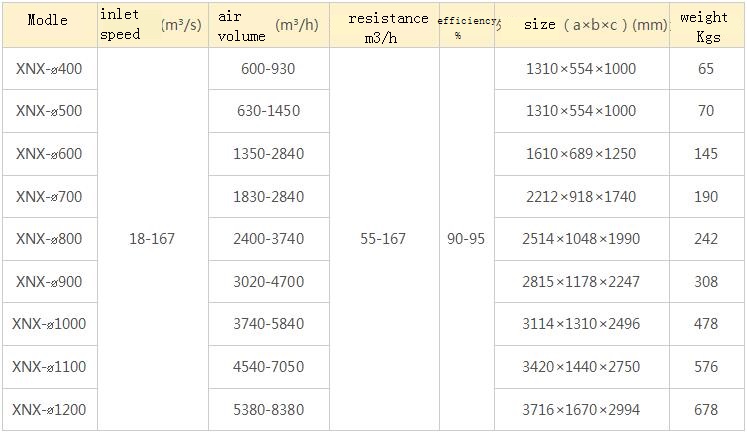

technical parameters