shot blasting machine hotline: 13806391438 0532-86110910

patent certificate

talents

Company brings together design, technology, electrical and computer technology personnel. Among them:

1. Mechanical engineers have expertise in computer-aided design (Computer Aided Design, CAD), mechanical design, mechatronics and pneumatic and hydraulic control technologies;

2. Process engineers have a good grasp of wear-resistant parts casting, machining center programming, heat treatment, tooling and process planning;

3. Electrical engineers are competent in electrical device selection, electrical design, programmable controller (PLC, including OMRON, GE, ABB, Siemens and other brands) programming, communication between PLC and upper computer and peripherals (including frequency converter, temperature controller, etc.), digital-to-analog/analog conversion and other technologies;

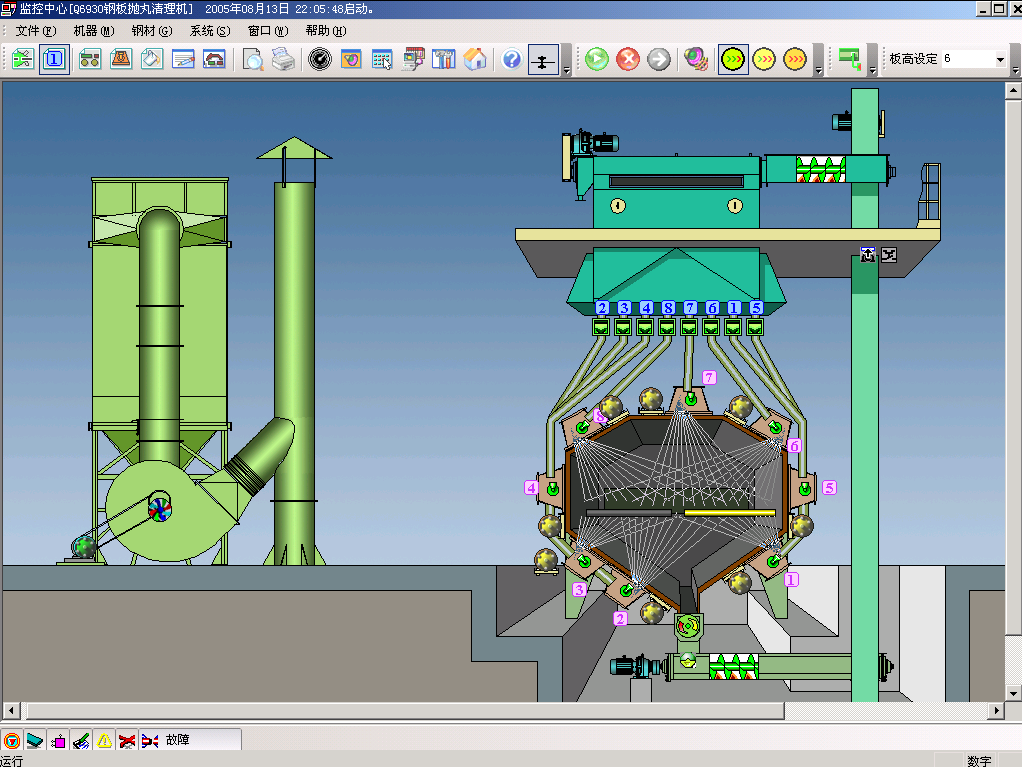

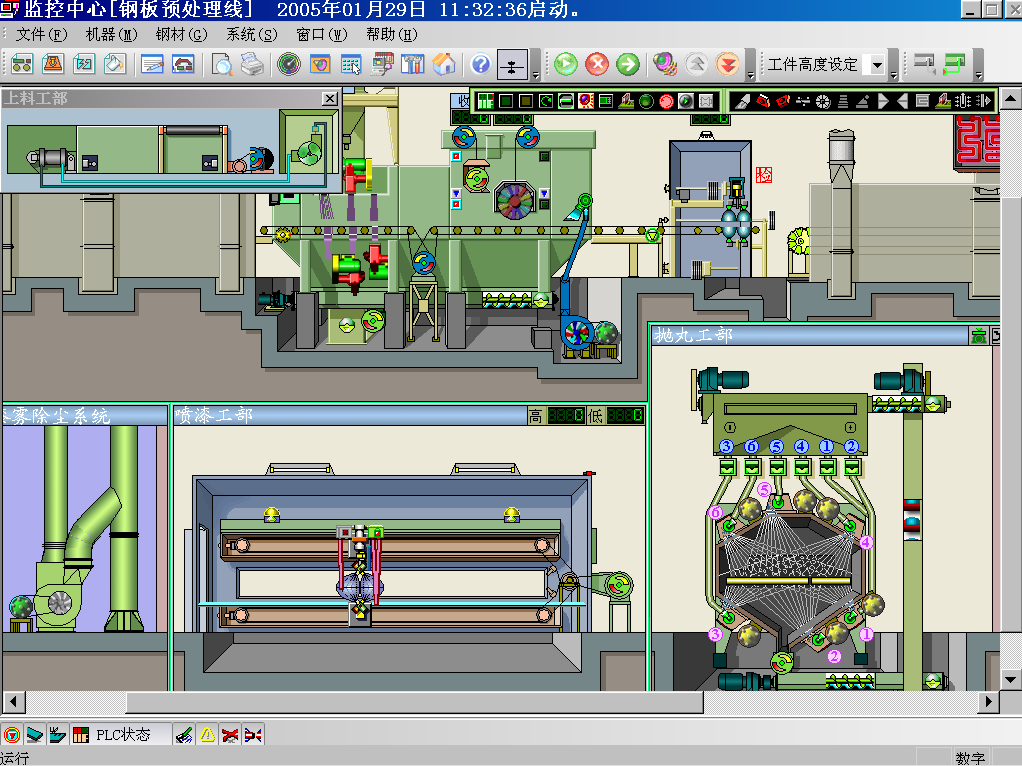

4. Computer engineers can independently complete the development of upper computer monitoring software (C language programming) and configuration (including iFIX, WINCC, Kingview, etc.) software and the application of touch screens of various brands. At the same time, the advanced three-dimensional CAD software can be used to optimize the design of shot blasting machine projectile map, chamber body and the whole machine.

Research Content

As a professional manufacturer of foundry machinery in China, the company's researchers have unique research in the same industry in the following areas:

1. Research on shot blasting device technology: model, wear-resistant part material, blade material, shape (straight line, curve) and size, adjustment of ejection direction, dynamic and static balance and selection of other auxiliary parts (such as bearings);

2. Projection principle and optimization design of shot blasting chamber body: trajectory of shot blasting, sealing of chamber body, protection of inner parts of chamber body (such as roller table, lighting lamp of shot blasting chamber);

3. Research on pellet circulation system: productivity, wind speed and air volume, pellet sand (ash) separation technology, research on uniformity of cloth in large separation separator, and technology of large lifting hoist, etc;

4. Dust removal and environmental protection technology: dust removal technology, noise elimination technology, etc;

5, industrial control and automation: large non-standard equipment (such as steel pretreatment line, etc.) of the full line of automatic measurement and control technology, work process simulation and factory-level production process data sharing.

Specific practices

company cooperated with well-known universities and institutes in China (Tsinghua, Shandong University of Technology and Jinan Foundry and Forging Institute) to complete the "computer-aided design (CAD) of shot blasting machine" software, and independently developed shot blasting scene simulation and three-dimensional simulation software of shot blasting effect (which effectively ensured the shot blasting effect and improved the shot utilization rate and the quality of the whole machine). At present, we carry out the optimization design of the projectile principle and the whole machine for each non-standard product.

In terms of industrial control, technicians independently completed the preprocessing line dynamic simulation monitoring software and a variety of touch screen monitoring programs using OMRON Hostlink, Schneider Modbus RTP/TCP and GE TCP/IP OPC Server.

Copyright @ Shandong Hachieve Holding Group Co., Ltd. Lu ICP 07020562

Pay Attention to Hachieve WeChat Public Number

Hachieve official Tik Tok number