multi-tube cyclone dust collector

Usage Introduction

multi-tubecyclone dust collector is a highly efficient dust collector suitable for capturing dry non-fibrous particulate dust. The main feature of the dust collector is that the cylinder body is inverted conical, thus reducing the possibility of dust-containing gas short-circuiting from the center of the cylinder body to the outlet. The multi-tube cyclone dust collector is equipped with a conical reflective screen to prevent the two air flows from rolling up the separated dust again and being carried out by the updraft, thus improving the dust removal efficiency.

The cyclone in the multi-tube cyclone is made of cast iron or ceramic, and the thickness is greater than 6mm, so it has good wear resistance. The dust collector is not only suitable for all kinds of boiler dust control, but also is the ideal equipment for dust control in metallurgy, mining, building materials, chemical industry and other industries.

The dust removal efficiency of multi-tube cyclone dust collector can reach more than 95%, and the dust collector body resistance is less than 900Pa. The normal operation of the boiler can be ensured by using the existing boiler induced draft fan. The dust collector has good load adaptability, and the dust removal efficiency is above 94% when the load is 70%.

working principle of multi cyclone dust collector:

Dust-containing airflow enters the cylinder through the inlet flue. The cylinder is a circular cylinder. Water enters the main cylinder from the water injection tank on the upper part of the dust collector, so that a layer of water film flows from top to bottom on the inner wall of the cylinder. The flue gas enters tangentially from the lower part of the cylinder and rotates and rises in the cylinder. Under the action of centrifugal force, the dust-containing gas always rubs against the water film on the inner wall of the cylinder, dust particles flow to the bottom of the dust collector with water flow and are discharged from the overflow hole. The bottom of the cylinder is sealed and a water seal groove is provided to prevent flue gas from leaking from the bottom. Cleaning holes are provided to facilitate cleaning of the bottom of the cylinder. After dust removal, the wastewater is discharged from the bottom overflow hole into the sedimentation tank, precipitated and neutralized, and recycled.

Specific Features

Multi-tube cyclone dust collector uses and features:

1. The processing air volume is large, the load adaptability is strong, and the ceramic movement of the ceramic multi-tube dust collector is smooth and durable, and will not cause blockage. The area is small, and the multi-tube cyclone dust collector can be installed flexibly according to the user's site conditions and local conditions. It can be placed indoors or in the open air.

2. It is suitable for dust control of industrial boilers and thermal power station boilers of various types and combustion modes.

3, for other industrial dust, the same can be used multi-cyclone dust collector treatment, but also the use of multi-cyclone dust collector for cement and other practical value of dust recovery.

4, one-time investment is small. Compared with the electrostatic precipitator, the total investment is less, compared with the water film dust collector, no circulating water, no secondary head, no waste water discharge, no need to increase the water treatment equipment.

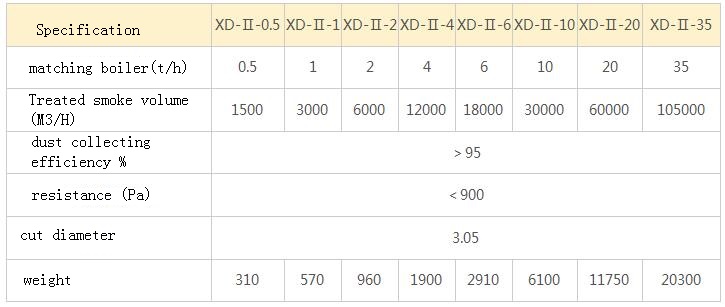

technical parameters