diffusion cyclone dust collector

Usage Introduction

Diffusion cyclone dust collector, also known as cyclone dust collector with inverted cone, is suitable for capturing dry non-fibrous granular dust, which can avoid secondary dust caused by dust, and has high dust removal efficiency.

Specific Features

diffusion cyclone dust collector is that the cylinder body is conical, thus reducing the possibility of short-circuiting the dust-containing gas from the center of the cylinder body to the outlet, and is equipped with a conical reflective screen to prevent the two air flows from being separated. The dust is rolled up again and brought out by the updraft, thus improving the dust removal efficiency. Diffusion cyclone dust collector is widely used in metallurgy, casting, building materials, chemical food, cement and other industries to capture dry non-fibrous particulate dust and dust removal, and can be used as recycling equipment.

diffusion cyclone dust collector structure design:

The structural proportion design of each part of the diffusion cyclone dust collector should be reasonable. The diameter and height of the outer cylinder of the cyclone dust collector have a greater impact on its performance. The smaller the diameter of the outer cylinder, the greater the centrifugal force of the dust particles given by the airflow movement. Therefore, the slender cyclone dust collector is more efficient than the short thick dust collector, and can capture the finer dust particles, but the fluid resistance is larger. It is generally believed that the height of the outer cylinder part of the cyclone dust collector with better performance is 1-2 times of its diameter, the height of the vertebral body part is 1-3 times of the diameter, and the angle of the vertebral body is 20 °-40 °.

The ratio of width to height of the cross section of the inlet of the diffusion cyclone dust collector is also very important. The smaller the ratio of width to height, the thinner the wellhead airflow in the radial direction, the more conducive to the separation and settlement of dust in the cylinder, and the higher the dust removal efficiency. Therefore, the import section is mostly rectangular, and the ratio of width to height is about 2.

Diffusion cyclone dust collector working principle:

Dust-containing gas enters the cylinder tangentially through the rectangular air inlet. Under the action of centrifugal force, the dust is thrown to the vessel wall and rotates downward with the rotating airflow. Most of the airflow is divergent by the reflecting screen, and rotates upward and is discharged through the exhaust pipe. A small part of the airflow enters the ash hopper with the annular gap between the dust reflecting screen and the cone. The diameter of the lower part of the shell increases, the rotating airflow slows down, and the dust is trapped in the dust is trapped in the dust, the gas is discharged to the exhaust pipe through the ventilation holes of the reflective screen.

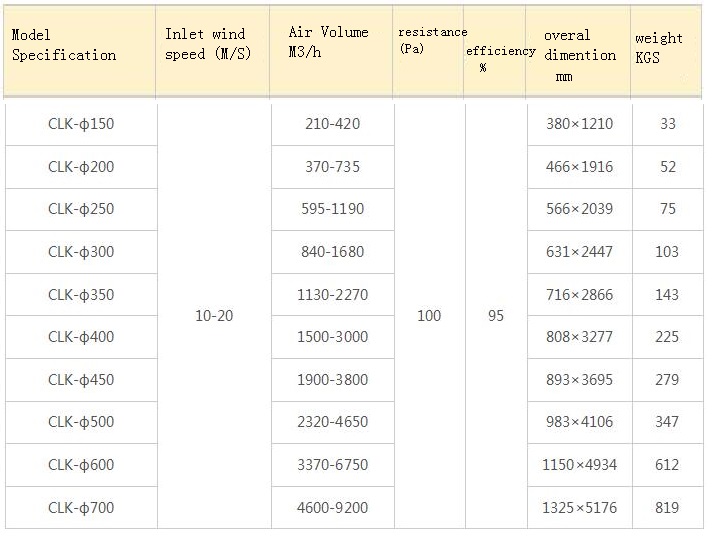

technical parameters

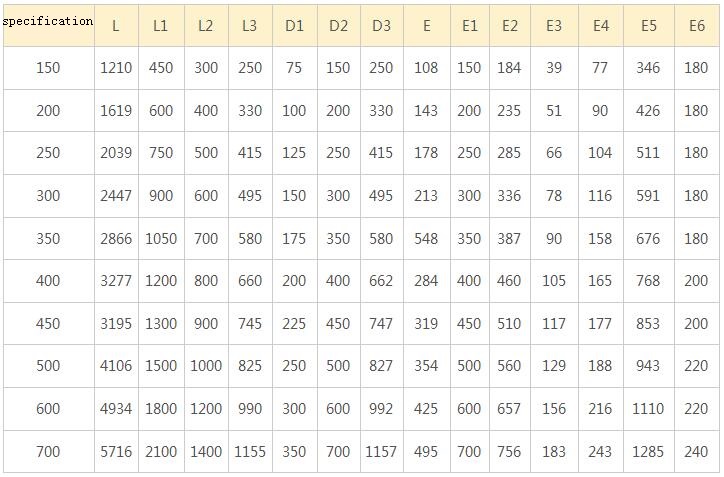

CLK diffusion type cyclone dust collector main size: